On Friday, a busload of folks left The Mannings in East Berlin and traveled about 2.5 hours to downtown Nazareth, PA, for a tour of Kraemer Textiles. This mill was built in 1887 and manufactured silk hosiery until World War II, after which they converted to spinning yarns. The Kraemer family sold to the Schmidt family, and the 4th generation of Schmidts is still running it. My group’s guide was Sharon Schmidt, wife of the current company president and developer of the yarn colors.

Kraemer only recently started making yarns for handknitters and handweavers. They used to spin lots of yarn for the apparel industry, but much of that work has moved overseas. They still make some yarn for apparel (including alpaca blend socks!) as well as for use in other industries. They make the neon yellow string that fly fishermen use to tie flies, for instance. They make yarn for buffing pads and carpet. They make one component of the Aida counted cross stitch fabric. The mill makes worsted spun yarn (not woolen spun). They do not dye fiber at all, so they either produce naturally colored yarn, or they buy bales of dyed fiber and blend it to create their custom dyed lines. Their signature line is called Perfection (70% acrylic, 30% wool) and it comes in dozens of gorgeous colors – this display is the first thing you see when you enter the yarn shop (and this is maybe half of the color line):

The mill makes worsted spun yarn (not woolen spun). They do not dye fiber at all, so they either produce naturally colored yarn, or they buy bales of dyed fiber and blend it to create their custom dyed lines. Their signature line is called Perfection (70% acrylic, 30% wool) and it comes in dozens of gorgeous colors – this display is the first thing you see when you enter the yarn shop (and this is maybe half of the color line):

Our mill tour began in the blending area. On Friday, they were beginning to make the colorway “Blueberry” for the Mauch Chunky line (which is 60% New Zealand wool and 40% domestic wool in a chunky weight). Blueberry is created from 4 shades of blue. The recipe indicates how much of each blue (by weight) and blenders create giant bales like this:

We didn’t see any Mauch Chunky being spun that day, but here is the lovely display from the shop. You can see that many of these colorways look heathered. More about that later…

Here is Sharon telling us about the giant bales of cotton in the warehouse we passed through... Kraemer can’t spin a 100% cotton yarn here, but they can blend cotton with other fibers using their machinery. It doesn’t even look soft, does it? It reminds me of insulation!

Kraemer can’t spin a 100% cotton yarn here, but they can blend cotton with other fibers using their machinery. It doesn’t even look soft, does it? It reminds me of insulation! Next we saw the giant carding machines. They are enormous and can process 1000 pounds of fiber in 8 hours. Don’t touch! I wish we had seen something like those blueberry bales going into the carding machine, but today was just plain white:

Next we saw the giant carding machines. They are enormous and can process 1000 pounds of fiber in 8 hours. Don’t touch! I wish we had seen something like those blueberry bales going into the carding machine, but today was just plain white: The carded fiber comes out the other end in these endless ropes which are coiled up in these tall skinny barrel-type containers.

The carded fiber comes out the other end in these endless ropes which are coiled up in these tall skinny barrel-type containers. Then the ropes go through another machine that “draws” them. I think this is like drafting or pre-drafting fiber before a handspinner spins it. The fiber is really soft and puffy at that stage:

Then the ropes go through another machine that “draws” them. I think this is like drafting or pre-drafting fiber before a handspinner spins it. The fiber is really soft and puffy at that stage:  Then it’s ready to be spun. This is a view of the back side of a spinning frame, pulling the ropes of fiber out of the barrels:

Then it’s ready to be spun. This is a view of the back side of a spinning frame, pulling the ropes of fiber out of the barrels:

The fiber goes up and over, and this is what it looks like from the front:

There were oodles of bobbins around. I’m not sure why some are metal and some are wood (forgot to ask) but I DO know why some are made of black mesh plastic – those are for orders that are going to dye houses. You can submerge the entire bobbin in dye and the mesh lets the dye permeate through to all the yarn.

There were oodles of bobbins around. I’m not sure why some are metal and some are wood (forgot to ask) but I DO know why some are made of black mesh plastic – those are for orders that are going to dye houses. You can submerge the entire bobbin in dye and the mesh lets the dye permeate through to all the yarn.

We were there on a Friday, so some of the spinning frames were finishing their work for the week and then being cleaned. You can imagine that a lot of fluff builds up in these things:

We were there on a Friday, so some of the spinning frames were finishing their work for the week and then being cleaned. You can imagine that a lot of fluff builds up in these things:

The bobbins get carted around the factory in this little cart that looks like it would have been at home in the 19th century: This is a winding frame – the yarn is wound off the bobbins (which stay in the factory) and onto cones (up top) for delivery to customers:

This is a winding frame – the yarn is wound off the bobbins (which stay in the factory) and onto cones (up top) for delivery to customers:

Here, Sharon shows us a skein winder. This thing isn’t very automated, but it makes the hanks of yarn that are twisted. The yarn goes around that thing that looks like the paddles on a paddleboat. Then the skein is taken off and twisted by hand: The ball winder is more automated. No balls were being wound when we passed through, but this is the machine:

The ball winder is more automated. No balls were being wound when we passed through, but this is the machine: When a ball comes off this machine, it looks kind of strange. See how big the hole in the middle is? That’s not what a ball of yarn looks like when we see it in a shop:

When a ball comes off this machine, it looks kind of strange. See how big the hole in the middle is? That’s not what a ball of yarn looks like when we see it in a shop:

That’s because the yarn has to go through one more step (whether it’s in a hank or a ball). This big scary-looking box is where the yarn gets “conditioned.” Basically, it gets a giant steam bath. Then the temperature comes down naturally and the doors are reopened and the yarn dries out. This step is equivalent to “setting the twist” in handspinning. We also saw some Tatany Tweed yarn being plied. (Tatany is 45% cotton, 55% acrylic.) The cones with the flecked yarn contain the plied yarn, and the singles are the more uniform looking cones above.

We also saw some Tatany Tweed yarn being plied. (Tatany is 45% cotton, 55% acrylic.) The cones with the flecked yarn contain the plied yarn, and the singles are the more uniform looking cones above. Here Julie feels the yarn. Again, this yarn hasn’t been conditioned yet, so the hand is kind of wiry and hard. These fibers are under a LOT of tension and receive a LOT of twist, so they don’t feel soft right away. That steam bath changes everything later, though!

Here Julie feels the yarn. Again, this yarn hasn’t been conditioned yet, so the hand is kind of wiry and hard. These fibers are under a LOT of tension and receive a LOT of twist, so they don’t feel soft right away. That steam bath changes everything later, though!

Finally, the yarn goes to be labeled and boxed. I don’t know why, but I find it amusing to see stacks of ball bands before they are attached to yarn:

Next stop, the warehouse:

We spent our last minutes with Sharon in “the lab” and she showed us how she develops the color lines. This shows ALL the colors of Perfection and how the colors fit into various color families within the line:

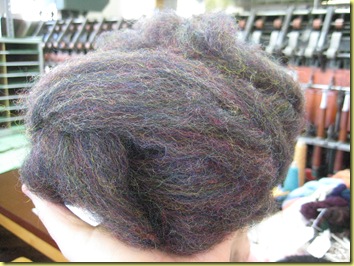

She also told us more about how colors are blended. We learned a new word: melange. A melange is like a heather in that many separate colors are blended to make the final colorway, but heathers are created from shades of a color, while melanges are created from wildly different colors. Here is an example of a melange – this one is the colorway “licorice” in the Mauch Chunky line: The final color reads mostly “black” (though it looks a bit lighter in my photo here), but you can see it contains yellow, white, green, blue, and red, in addition to black. It’s all about the proportions.

The final color reads mostly “black” (though it looks a bit lighter in my photo here), but you can see it contains yellow, white, green, blue, and red, in addition to black. It’s all about the proportions.

I ended up buying a sweater’s worth of Tatamy Tweed Worsted for a sweater for Boy 1. He has been asking for one, and he DOES love to wear sweaters. I wouldn’t normally be interested in knitting with a 45% cotton/55% acrylic blend, but several women in our tour group said they’d used this for toddler sweaters and it wears like iron. One said that a mother had been washing it for 3 years and it looks good as new for her next child. So I thought it was worth a try… I picked a color called “Flannel,” which has flecks of red and even a little greenish-blue in it:

I’ll wait until next fall to knit this sweater, though, since I’m never sure how much a child will grow in a season.

I’ll wait until next fall to knit this sweater, though, since I’m never sure how much a child will grow in a season.

All in all, Julie and I (and the rest of the busload) had a wonderful day. Thanks to The Mannings for organizing this field trip! And thanks to Kraemer for hosting us. They don’t do drop-in mill tours for the public, and this was a special arrangement for Mannings customers. I understand that there were 70 or so of us in all (though some drove separately).

It’s wonderful to see a historic mill thriving here in the U.S. I hope that Kraemer Textiles is around in another 100 years.

Amazing! Almost as good as being on the actual tour. Thanks for sharing!

ReplyDeleteGreat tour! Although I really would have like a picture of you getting all Norma Rae and standing up on the equipment holding a Union! sign. That spinning equipment looks just like the machines in the movie.

ReplyDeleteBoy 1 is gonna love a sweater out of that yarn!